2016-10-06

Mechanical alternative for flexible force transmission

Bowden cable system of RINGSPANN RCS wins over manufacturer of professional circular saws

As bi-directional control, actuation and operation elements, the remote control systems of RINGSPANN RCS prove their worth each day in the railway, aviation and motorsports industry. However, more and more design engineers from other industries are also discovering the premium-processed functional elements as a mechanical alternative for the flexible transmission of forces. A current example of this is the use of a Bowden cable system from Oberursel in the new undertable chop saw of a renowned machine tool manufacturer. This push/pull cable was benchmarked the most reliable and most economical operation solution.

Oberursel, October 2016. – When thinking about the flexible transmission of forces from a fixed starting point to a remote or even mobile component, design engineers often think too much. This leads every now and then to pneumatic, hydraulic, electrotechnical or complex joint rod systems being created, which are technically oversized and much too expensive. And yet there is a solution for the transfer of pulling and pushing forces which is economical and boasts a design that has stood the test of time: the push/pull cable systems of RINGSPANN RCS. These actuation and control elements, which are nearly similar to the classic Bowden cable in terms of the way they function, are purely mechanical remote control systems with which high forces can be transferred over winding metre-long distances. They meet high quality standards, have technically sophisticated inner workings and are convincing and reliable endurance runners even in safety-relevant applications. In practice however, it is shown again and again that what is probably the most important prerequisite for the successful use of a bi-directional push/pull cable is its correct application-specific dimensioning.

Correct dimensioning as the decisive factor

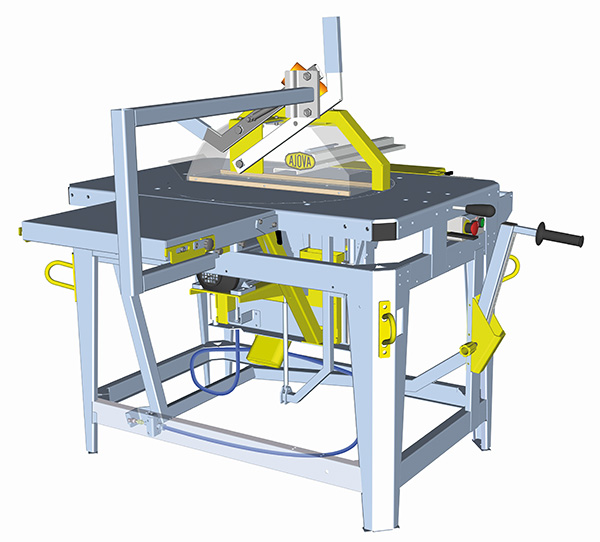

Dirk Strauch, technical director of the renowned circular table saw manufacturer Avola, recently discovered for himself just how important an accurate evaluation of the installation situation and a precise calculation of the forces at work are: “For our new undertable chop saw Variant 450 we were urgently looking for an economical operation solution for the simple and reliable adjustment of the mobile saw blade.” This variability of the saw blade is the key feature of the new circular saw from Avola, (www.avola.de) making it a very flexible separating tool that gives roofers and carpenters the possibility of realising seven different cutting variations and of also performing double mitre cuts accurately and fast. A design engineering prerequisite for this versatility is the height-adjustable saw blade borne in a 150° turntable and inclinable over 60°. What proved to be a particular challenge during the development phase was finding the best vertical adjustment method for the chop cut. “In order to make precise, ergonomic and safe raising and lowering of the saw blade possible for the user with a scaled hand lever, we absolutely needed a dependable and smooth adjustment solution”, Dirk Strauch recalls. The problem: since the drive and saw blade form a functional unit, it is not only the saw blade (Ø 450 mm) that has to be moved to the desired height position by operating the lever, but the 20 kg electric motor underneath it (3.2 KW) must always be moved with it as well. A further requirement is for this complete unit to also remain easily and quickly adjustable for the worker when swivelling and turning.

How does the force get from here to there?

Dirk Strauch and his developer team were therefore confronted with a classic problem of force transmission. How could the pushing and pulling forces needed for height adjustment be taken from the hand lever at the front side of the circular table saw to the mobile action unit of saw blade and drive via the rather winding undertable landscape? Pneumatic, hydraulic or electrical solutions were ruled out from the beginning. They would have substantially increased the price of the entire circular table saw and would have thus jeopardised its competitiveness. Avola technical designers found complicated joint rod frames to be too bulky and delicate. Which is why a solution from the area of Bowden cable systems was favoured. “However, the Bowden cables tested by us fulfilled neither our quality standards nor our dependability requirements”, underlines Dirk Strauch.

Only when the technical director of Avola got in contact with the German enterprise RINGSPANN RCS did a solution come about for the operation and adjustment problem of the mobile saw blade. RINGSPANN RCS is one of the world’s leading manufacturers of so-called “remote control systems” and, according to managing director Christian Kny, it is the company’s philosophy to not only place great importance on a high product quality but particularly on a detailed analysis of the customer’s installation situation. This includes the accurate calculation of efficiencies – those of push/pull cables for example. “We have profound practical expertise in this field and always place these aspects at the forefront of our consulting discussions”, says Christian Kny. Following a detailed on-site analysis at Avola, RINGSPANN RCS technicians determined the dimensioning of the required cable system taking numerous factors into consideration (forces, installation layout, bending radii, cable length, vertical travel and much more besides) and presented the developer team of the circular saw manufacturer with a 270 cm long, maintenance-free push/pull cable from the RINGSPANN RCS series 283 as a solution to the problem.

Eureka moment in the development department

“This Bowden cable working in push and pull direction was a real eureka moment for us. In our internal tests, it outshone all previous ideas in terms of smoothness of movement and functional reliability” reports Dirk Strauch of Avola. Owing to its application-specific design calculation, the push/pull cable from RINGSPANN RCS is neither affected by the weight of the three-phase motor nor by the inclination of the saw blade – it follows all movements, meaning that positioning the height by lever is never any trouble. “Earlier Bowden cable products often proved to be very unmanageable and required far too much effort and strength for their actuation alone”, reports Strauch. The push/pull cable customised for Avola on the other hand retains its functional reliability and smoothness of movement, even at high loads and in any position. These operation elements of the series 283 from RINGSPANN RCS can transfer pulling forces of up to 4500 N and pushing forces of up to 3150 N. As well as the lifetime lubrication of these push/pull cables, the teflon coating of the inner member also makes an important contribution to the low-loss force transmission. For it ensures that the inner member always remains freely movable and slidable in its guide sleeve despite the spiral-shaped twisting explained by its function.

Rigid or swiveled?

An important aspect of the cable design is also the dimensioning of the mounting assembled at the stainless steel rod ends. RINGSPANN RCS generally offers two possibilities here: rigid without joint or swiveled with joint. For the new circular table saw of Avola, this had the great advantage that the cable mounting at the hand lever (so at the input side of the force) could be implemented as a mobile articulated joint. The several centimetre long connecting piece can swing 8° around the longitudinal axis of the cable and thus follow the tangential movement of the lever without any problems during the adjustment procedure. “Since this makes it possible to guide the steel cable inner member, which is a central element of force transmission, more linearly and with very low friction, our push/pull cable achieves an optimal efficiency. The user ultimately notices this in the smoothness of operation”, explains company boss Christian Kny. In a YouTube-video, RINGSPANN RCS has very clearly illustrated the functioning of the articulated mounting.

With RINGSPANN RCS’s push/pull cable boasting a precise design calculation and application-specific configuration, circular table saw manufacturer Avola has ultimately got a very key design engineering detail for the implementation of its highly flexible undertable chop saw. This case is one example of many other dynamic and mobile applications where these flexibly installable bi-directional cable systems for the mechanical transmission of forces are the best solution both economically and in terms of design engineering. Details of the possibilities offered to product developers and design engineers are given in the current complete catalogue of RINGSPANN RCS. Over 60 pages, it informs not only about the many different versions and delivery forms of the push/pull cables, but also about the wide range of accessories geared to these, such as operating levers, pedals, clevises, ball joints, mountings clamps and brackets and much more.