2016-11-23

Successful acid test for the benefit of motor racing

New disc actuated bush clamping mandrel by RINGSPANN wows gearing engineers

During the grinding of high-precision spur wheels for motorsports gears, the new mechanical disc actuated bush clamping mandrel HDDS from RINGSPANN showed its potential for the first time under extreme conditions. The experienced gearing experts of a Swiss company were positively surprised by the accuracies that could be achieved with it.

Bad Homburg, November 2016. - In the manufacturing of customer-specific gear wheels for international motorsports, the highest geometrical accuracy requirements apply. These are significantly higher than the standard quality requirements in normal automotive engineering. While automobile manufacturers for gear wheels generally expect a gearing quality in the region of 6 in accordance with DIN 3961, higher gearing qualities of grade 4 or even 5 are required for racing. “Reliably implementing such extreme quality requirements places the highest demands on machines, tools and technicians. And because the clamping tools used also play very crucial part in this, gearing engineers constantly keep their eyes open for optimization potential in this area," reports Volker Schlautmann. The director of the RINGSPANN clamping fixture division is only too aware of the growing quality requirements in gearing technology and has therefore come up with a new (and now patented) mechanical disc actuated bush clamping mandrel: The HDDS. This innovative inner clamping system was presented to a larger audience for the first time at the AMB 2016 trade fair as a highly precise and economically attractive alternative to hydraulic expanding clamping tools.

Innovative alternative to hydraulics

According to Volker Schlautmann, the new RINGSPANN clamping mandrel earns plaudits for its true running accuracy of ≤ 5 µm and can take workpieces with bores of up to tolerance class IT10. It was also developed with the aim of significantly reducing the costs for the necessary feeding and positioning technology in fully automated operation. “We have aroused the curiosity of many gearing specialists, who now want to know what the new HDDS is really able to achieve in their machines during the high-precision grinding of spur wheels. Backed up by technical measurements of course," stresses Schlautmann.

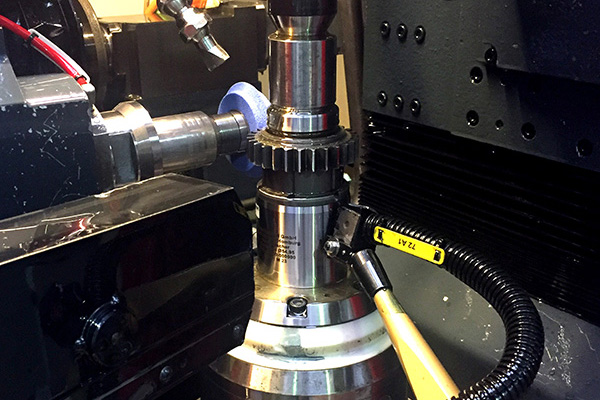

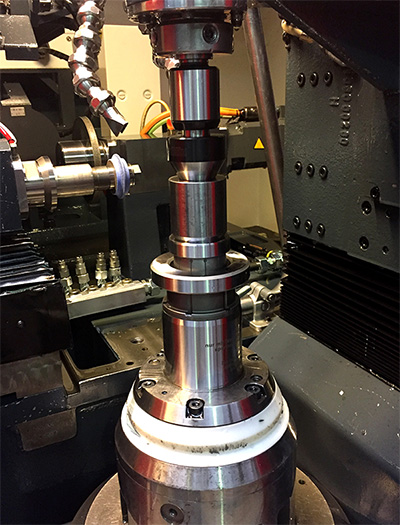

For this reason the man from RINGSPANN presented, with the new mechanical disc actuated bush clamping mandrel, to the parent plant of a renowned Swiss specialist for gear wheel technology where a practical test was carried out. A suitable workpiece had already been selected there: A precision spur wheel for the special gear of a sports car set to hit the tracks at international long-distance races. A Höfner Helix 400 grinding centre was used for the machining. Its installation space accommodates a fixed hydraulic base mounting, which the HDDS from RINGSPANN was clamped into vertically enabling it to be centrically aligned. The gearing engineers then manually clamped a neutral control workpiece in place so as to check the axial run-out accuracy and true running accuracy of the mechanical disc actuated bush clamping mandrel with a tactile measuring device accurate to the micrometer. The result caused the ears of those present to prick up: The measuring device showed ≤ 2 µm for the axial run-out and ≤ 3 µm for the true running – amazing accuracies for a mechanical workpiece clamping system without additional alignment effort! What precision could then be achieved when grinding the gearing?

Following these preparations, a tailstock was mounted – fed in from above. However, its travel distance turned out to have been dimensioned a few inches too short to reach RINGSPANN’s disc actuated bush clamping mandrel. A spacer therefore had to be used at first to bridge the gap, although it could not be aligned. Despite this improvisation, the spur wheel blank was now clamped on with the HDDS and the grinding process started.

Surprise on the measuring device

After a machining time of approximately 13 minutes, it was time for the moment of truth. The finished spur wheel was removed from the HDDS and tactile measurements performed on it in a coordinate measuring system of the Swiss company. The result was a real surprise: The geometrical accuracy of the involute gearing (a term from mathematics which gearing engineers use to denote the force-optimized shaping of the tooth flanks) was well within the tolerance limits. "Despite the additional bridging element between the tailstock and the workpiece, only about two thirds of the permissible tolerance was exhausted," underlines Volker Schlautmann of RINGSPANN.

And as if that weren′t enough: spurred on by the excellent results achieved until then, the gearing engineers started a further test run, but this time without the tailstock fed in from above. The new disc actuated bush clamping mandrel by RINGSPANN then showed its real strength, for "the result was even better when grinding without the tailstock since just half of the permitted tolerance had been exhausted," reports Schlautmann. A gearing quality of grade 4 could even be achieved in this way, and without the clamping fixture being realigned! "Manufacturing just continued – but without the tailstock. The results even exceeded our own expectations", says a pleased Volker Schlautmann.

Higher accuracy at lower costs

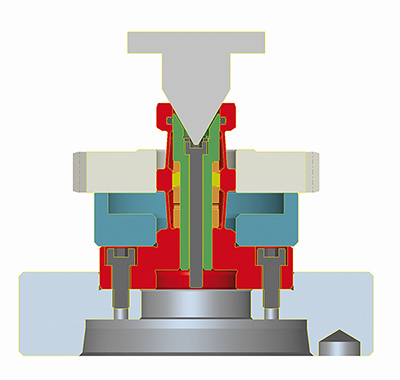

With its new mechanical disc actuated bush clamping mandrel, RINGSPANN has had a huge success. For gear wheel manufacturers and other users in the area of fine machining, this is a very economical alternative to hydraulic expansion clamping tools. “Apart from the high accuracies achievable with the HDDS, the absolute expansion of our new disc actuated bush clamping mandrel is also up to four times greater. This does not only mean a higher degree of flexibility for the user in machining, but is particularly of great importance for the simple implementation of fully automated manufacturing concepts,” Volker Schlautmann explains. It is important to mention here that, for pure reasons of physics, hydraulic expanding clamping mandrels have quite a small expansion rate. This requires a high precision from the handling systems used for feeding, which can usually only be achieved with considerable additional investments in measuring and control technology. This problem disappears with the new mechanical disc actuated bush clamping mandrel by RINGSPANN.

Clamping without risk of leakage

A further advantage of the new HDDS is that, unlike hydraulic clamping systems, it is not subject to a risk of leakage. This offers the user a greater process reliability, since a leak on a hydraulic extension clamping tool always goes hand in hand with malfunctioning, disassembly from the machine and repair by the manufacturer. "If there is any wear at all with our new mechanical disc actuated bush clamping mandrel, then it is merely the clamping discs used – which are also quality RINGSPANN products – that are subject to minimal wear. However, these can be exchanged very easily by the user; and the HDDS does not even need to be taken from the machine spindle to do so", says Volker Schlautmann.

Finally, it should be mentioned that the new inner clamping system from RINGSPANN can also be easily used for workpieces with very short clamping lengths. The reason for this being: The new disc actuated bush clamping mandrel performs a pull-back action, where the workpiece is pressed against a backstop and aligned – also ensuring an accurate centering and clamping of workpieces with short clamping lengths. Even bores interrupted by a groove for example can be reliably and precisely taken by the HDDS from RINGSPANN without any supplementary aids.

For Volker Schlautmann, the inventor of the mechanical disc actuated bush clamping mandrel, the excellent results of the practical tests completed at the Swiss gear wheel specialists are a final confirmation of the new inner clamping system’s high performance. "Following a number of successful test series performed previously, we were just waiting for a case of application with as extreme requirements as this one. We can now complete the design of our HDDS standard series for clamping diameters of 32 to 85 mm with a view to building up an inventory of quickly retrievable semi-finished products. The new mechanical disc actuated bush clamping mandrel HDDS from RINGSPANN will be available at short notice from 2017 onwards", Volker Schlautmann assures.