2025-05-27

With closed eyes to peak performance

RINGSPANN Kempf presents a new cardan shaft for the paper and heavy-duty industry

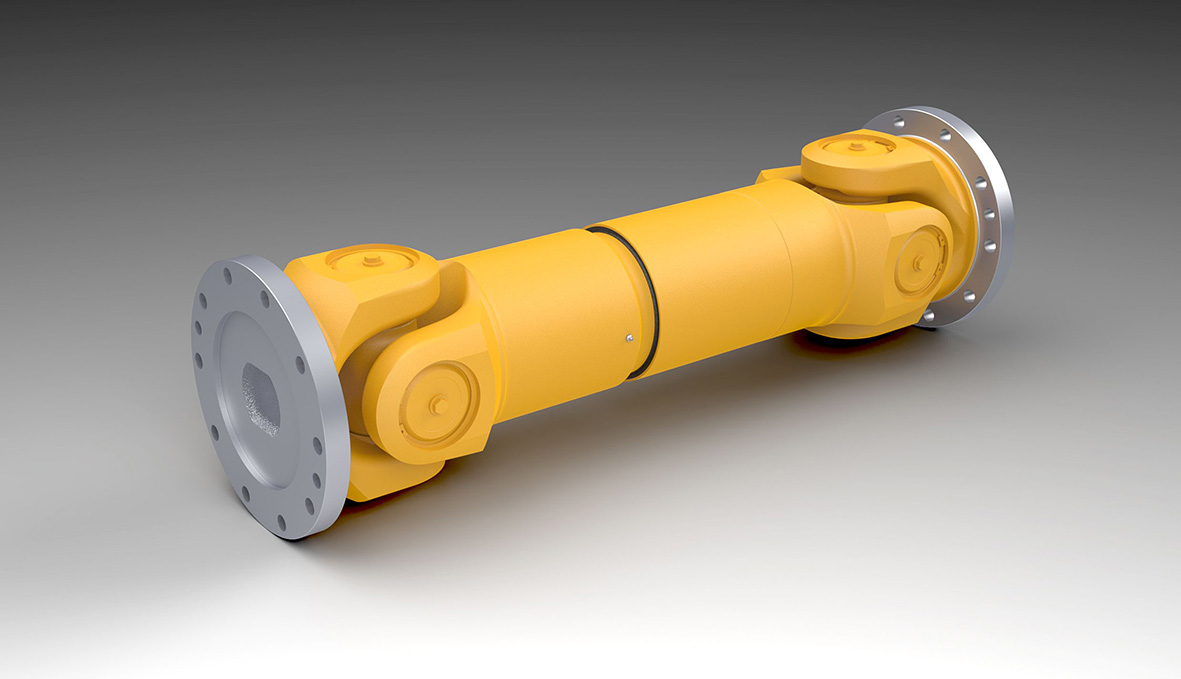

RINGSPANN Kempf presents a new cardan shaft for the paper and heavy-duty industry RINGSPANN Kempf has launched a new cardan shaft series as the first milestone in its latest product offensive. The company offers cardan shafts for torques of up to 290000 Nm (catalogue torque Mk) and thus now represents the upper performance peak in the current portfolio of the renowned manufacturer. This premium product Made in Germany opens up further optimization potential in particular for drive technicians in the paper processing and packaging machine industries, as well as plant manufacturers in the international steel, oil and gas industries.

Bad Homburg, May 2025. – „The integration of Kempf Universal Cardan Shafts into the RINGSPANN Group at the end of 2024 provides the traditional German cardan shaft manufacturer with new, far-reaching development and sales prospects. This is being expressed at present, among other things, in the current product and image offensive, in the course of which RINGSPANN Kempf is expanding its range of gimballed cardan shafts with an additional series. "With a torque capacity of up to 290000 Nm (MK), the new 160 series now marks the upper performance peak of our broad-based cardan shaft range," says Jochen Helfrich, Managing Director of the company. Cardan shafts with such above-average catalogue torques are of particular interest to manufacturers of drive systems for heavy-duty systems – for example, for steel production or oil and gas extraction. For many other areas of mechanical engineering, plant engineering and vehicle construction, on the other hand, it is important that RINGSPANN Kempf is now able to offer an extraordinarily large and finely graded selection of cardan shafts, which is now provisionally at the peak with the new 160 series. In concrete terms, this means that the company now provides small, medium and large cardan shafts with torque capacities from 3200 Nm to 290000 Nm ready for installation in 19 series. With this enormous range, it is just as attractive a supplier for manufacturers of paper processing and shredders, for example, as it is for developers of drive units for railway technology, shipbuilding and energy technology. "Currently, it is the paper and packaging machine industry in particular that is increasingly perceiving us as a premium partner for high-quality cardan shafts," reports Jochen Helfrich.

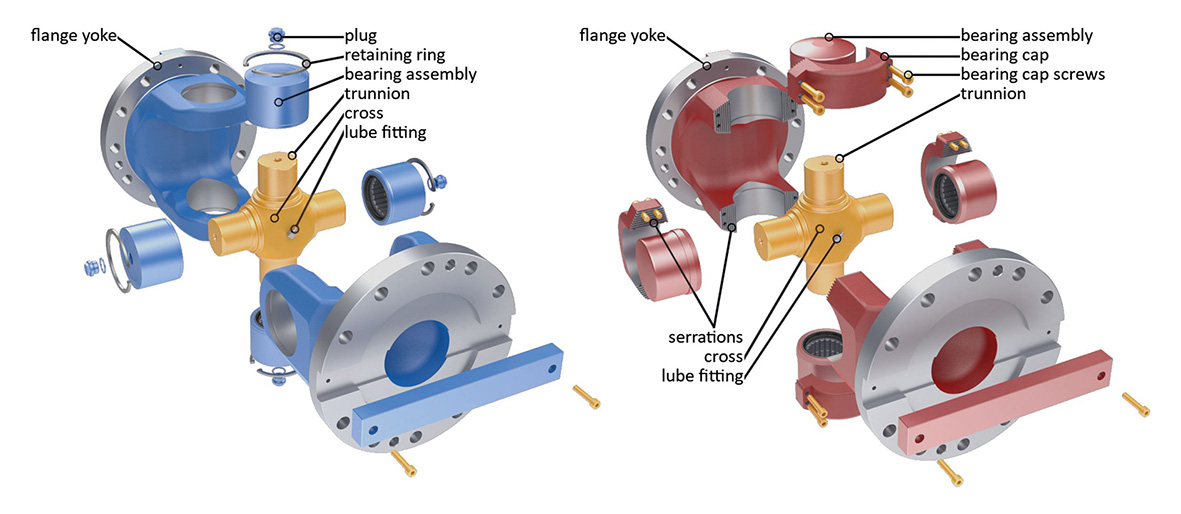

Added value through closed-eye design

The new cardan shafts of the 160 series are high-quality top products Made in Germany. Both their design and their production are based on an expertise that is the result of many decades of experience in the field of cardan shaft production. This is reflected in various technical features that are typical of RINGSPANN Kempf products. "For example, we rely uncompromisingly on the closed-eye design. This means that the new 160 cardan shafts also have closed bearing eyes. Especially in demanding, critical applications, this design detail offers considerable advantages over a split-eye design," emphasizes Jochen Helfrich. In the closed-eye design, the clevis and bearing housing are made of one piece, which ensures ideal load distribution between journal, bearing and clevis. There are no screws or gears in the clevis that require additional maintenance or could cause premature wear or corrosion. Since there is no installation space for screws and gears to consider, the bearings can be dimensioned as large as possible. For heavy-duty applications, it is also highly relevant that the one-piece clevis bearing bore significantly increases the service life of the bearings. A further contribution to reduced MRO expenditure is the fact that all clevis parts at RINGSPANN Kempf are compatible across all assemblies. For the production of the cardan shaft components, high-quality quenched and tempered, case-hardened and structural steels are used without exception.

Flexibility through length compensation

The new cardan shafts have rotation diameters of 390 mm, and their connection diameters range from 390 to 480 mm. They have a proven radial-axial combination seal system, and their high-quality bearings are the result of close cooperation between RINGSPANN Kempf and well-known German rolling bearing manufacturers. The length compensation (DIN-5480-200x3), which is manufactured with a high-precision elvolvente profile, opens new wide areas of application and offers flexibility in installation. The cardan shafts can be pushed together to an assembly length of up to 1200 mm. Their maximum diffraction angle is 18°. They are delivered in a low-maintenance or – depending on the customer's requirements – maintenance-free version. The balancing of the cardan shafts is also customer oriented. It complies with the DIN ISO 1940-1 standard (formerly VDI 2060) using the G16 or G40 balancing quality levels. "As with all our cardan shafts, the new series 160 is custom-made according to the customer’s specifications or application-specific requirements," says Jochen Helfrich. ms

After-sales service for cardan shafts

The journal cross and bearing bush as well as the profile pin and profile sleeve are among the components whose careful observation, maintenance and, if necessary, repair can significantly extend the service life of a cardan shaft. RINGSPANN Kempf therefore offers its customers a comprehensive after-sales service that goes beyond the usual industry standards. The focus is on mobile maintenance teams that specialize in inspections at short notice at the customer’s site. Their range of services ranges from the initial on-site inventory to repair and parts replacement, to the creation of individual maintenance plans and detailed service reports. At present, operators of paper processing and packaging machines in particular are taking advantage of this offer to avoid system failures from the outset and reduce downtimes.