Frictional shaft-hub-connections

Frictional shaft-hub-connections are standard machine elements used to connect shafts

and hubs. They are capable of transmitting torque, axial forces, radial forces and bending moments.

Shrink Discs and Cone Clamping Elements

Among the frictional shaft-hub-connections Shrink Discs and Cone Clamping Elements take an important position. By tightening clamping screws conical surfaces are pulled together generating radial forces; these forces provide the required frictional connection between the parts involved in the transmission of torques or forces.

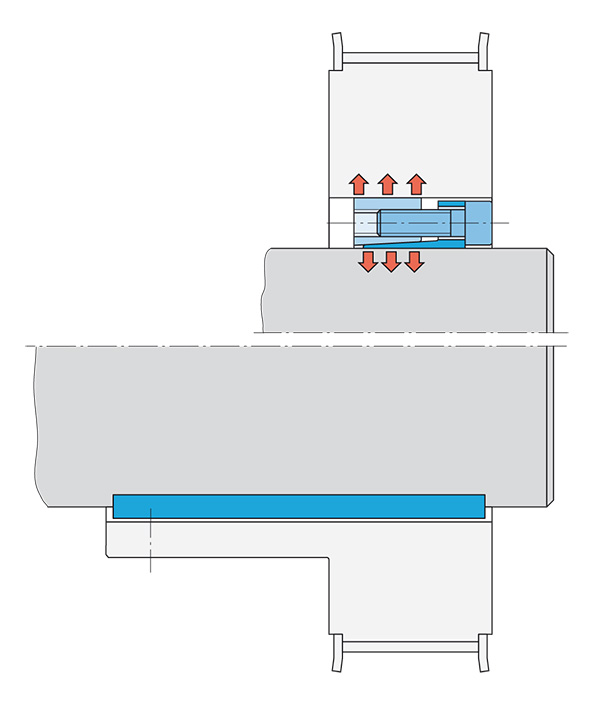

Shrink Discs and Cone Clamping Elements are capable of transmitting much higher torques than conventional positive connections with keyways. The shafts can be designed smaller and shorter. The relationships between shaft diameter and shaft length are illustrated in the example shown in the figure. In this comparison, the same torque is transmitted via a Cone Clamping Element (upper half of the figure) and via a keyway connection (lower half of the figure). The Cone Clamping Element design offers a much more compact and cost effective solution.

Star Discs

A special category of frictional shaft-hub-connection is the RINGSPANN Star Disc. Connections using Star Discs are ideally suite to applications requiring repeated adjustment with adjustment devices in a short overall length.

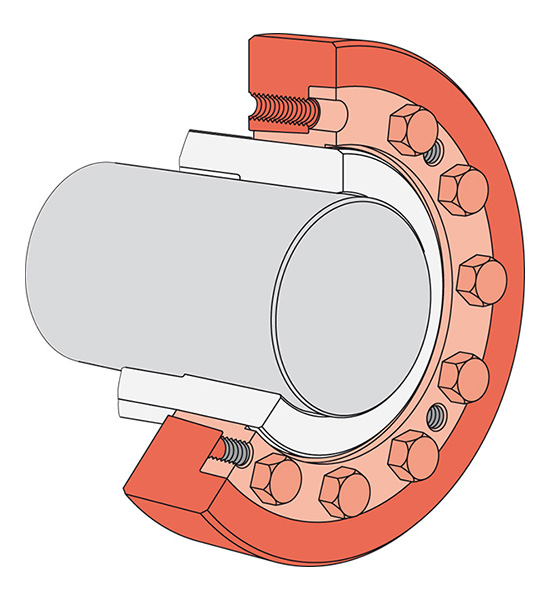

Clamping Systems for torque motors

Both complete torque motors and integrated torque motors can be connected by friction to machine shafts with RINGSPANN torque motor clamping systems. In addition to secure, backlash free torque transmission, these systems also ensure precise centring of the torque motor on the machine shaft.

Star Spring Washers

RINGSPANN Star Spring Washers are particularly light spring elements with linear or non linear spring characteristic. They are suitable for application as pressure elements in precision machines and as pressure springs for taking up free movement, and for reducing noise in ball bearings.

Upper half of figure: Shaft-hub-connection with Cone Clamping Element

Lower half of figure: Shaft-hub-connection with keyway

Advantages of frictional shaft-hub-connections

- Backlash free connections

- Ideal for reversing operation

- Simultaneous transmission of torque and axial force

- Easy alignment of hub to shaft

- Compact solutions due to high power density

- Reduced costs due to simple shaft and hub geometry

- Connections can be released even after long operation time

Categories of RINGSPANN shaft-hub-connections

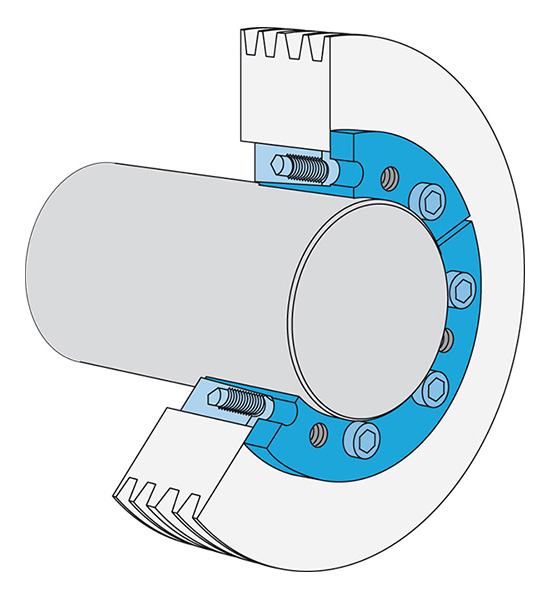

Shrink Discs

Shrink Discs are external clamping connections for the backlash free fastening of hollow shafts or hubs to shafts. By tightening clamping screws conical surfaces are pulled together generating radial forces; these forces press the hollow shaft onto the shaft. Torques or axial forces can be transmitted frictionally from the hollow shaft to the shaft. The Shrink Disc itself is not involved in the transmission of torques or axial forces. The radial clamping forces which act through the circumference of the hollow shaft also ensure an optimum centring to the shaft.

Shrink Discs are used, for example, to fasten machine shafts to gearboxes with hollow-shafts.

Cone Clamping Elements

Cone Clamping Elements are internal clamping connections for backlash free fastening of hubs on shafts. By tightening clamping screws conical surfaces are pulled together generating radial forces; these forces create a frictional connection between the Cone Clamping Element and the shaft as well as the hub. Torques or axial forces can be transmitted from the shaft via the Cone Clamping Element to the hub.

Cone Clamping Elements are used, for example to fasten sprockets, flywheels, levers, pulleys, brake discs or conveyor-belt drums.

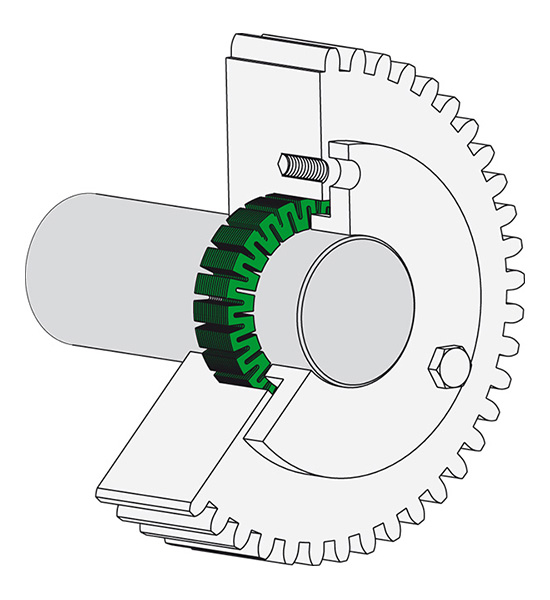

Star Discs

Star Discs are flat-bevelled rings which are slotted on the outside and inside. An external axial actuating force is translated by the Star Disc into a much higher radial force. This force creates a frictional connection between the Star Disc and the shaft as well as the hub. Generally, Star Discs are installed in a multiple arrangement as a disc pack. This makes it possible to adjust the transmissible torque to the requirements of the specific application.

Shaft-hub-connections with Star Discs are used wherever frequent clamping and release are required, for example in adjustment devices.